Other Functions

$FAPPLY(a) |

Activate composite post-processor component Returns: Logical |

This function is used select the composite post-processor component to activate, as identified using the component designator keyword. A value of $TRUE is returned if a component change is made. When the component is changed, the machine shutdown macro of the current active component is first executed, followed by the machine startup macro of the newly activated component.

$FAPPOS(id[,type]) |

Get SmartPATH™ positioning motion Returns: Sequence |

This function is used to examine the motions generated in a SmartPATH positioning sequence. The id parameter specifies the motion number for which information is desired. The total number of motions generated in the positioning sequence can be obtained using the $APIDN system variable. Specifying an id outside the range 1:$APIDN will result in a $NULL sequence being returned. The type of motion data returned is as follows:

- 1:

CL part frame, equivalent to the $P2 motion macro variable

- 2:

Machine frame, equivalent to $XM, $YM… macro variables

- 3:

Workpiece frame, equivalent to the $P3 motion macro variable (default)

If type is omitted, coordinate data is returned in the workpiece frame.

$FARG(a) |

Extract argument Returns: Any |

This function is used to get an argument from the data portion of the record matching the current macro. $FARG returns the value of argument number a. The resulting value of an $FARG function call could have KEYWORD, REAL or STRING type.

$FDIALOG(s1[,s2] ) |

Activate a dialog Returns: String |

This function can activate a dialog that has been defined inside the post-processor, or one that has been saved to a file on disk. The first s1 parameter is a string specifying the name of the dialog. The second s2 parameter is optional. If present it specifies the name of the external file that contains the dialog. The $FDIALOG function returns a text string, which is the label of the button that was pressed to close the dialog (e.g., “OK”).

Each “control” in the dialog (e.g., checkbox, combobox, etc.) is associated with a macro variable when the dialog is created in QUEST. When the dialog is activated in a GENER macro, each dialog control is initialized to an appropriate state based on the current setting of its associated macro variable. If a dialog control references a variable that has not yet been defined, a local variable is created and set to the default value defined within the dialog. When the dialog exits, the macro variables associated with each control take on whatever value the user may have entered. In cases where the user value’s type is ambiguous, the dialog processor will try to maintain the same variable type on exit as there was on input. Strongly typing variables with the DECLAR macro command will ensure the correct return value (the dialog processor will issue a diagnostic and keep the dialog active if the wrong type of data is entered, for example text in a numeric field).

Combobox and Drop-list controls can optionally have a second associated variable that defines the set of valid choices. These variables must be initialized as arrays or sequences. They must be set to appropriate values, before calling the $FDIALOG function.

There are three button types in a dialog: OK, Cancel and Reset. Buttons with OK and Cancel types cause the dialog processor to return control to the macro. Reset type buttons don’t return control to the macro, they instead reset the dialog controls to their initial values and keep the dialog active. OK type buttons return control with macro variables updated; Cancel type buttons return control with macro variables unchanged (but initialized if necessary). The $FDIALOG function returns the text string associated with the OK or Cancel type button that was pressed (buttons can be labeled with any text and there can be multiple buttons of the same type).

$FDIST(x1,y1,z1,x2,y2,z2) |

Distance between points Returns: Numeric |

This function the distance between two points defined by x1,y1,z1 and x2,y2,z2.

$FDK([q]) |

Convert machine coordinates to workpiece coordinates Returns: Sequence |

This function returns the workpiece coordinate that represents the specified machine position (see $FIK for the reverse functionality). The return value is a sequence of length 6, representing the workpiece XYZIJK tool position. The input is a sequence q of length 6 representing the machine axes positions as defined by the current $AXES system variable. Sequence values for inactive axes are ignored, as are excess trailing zero sequence values. Missing trailing sequence values are replaced by the current machine position. Use the {} sequence operator to create an input machine coordinate sequence if necessary. For example, to obtain the workpiece equivalent position of the machine coordinate X=0, Y=0, Z=10:

W=$FDK({0,0,10})Calling $FDK without a machine coordinate argument returns a sequence equivalent to: <$XC, $YC, $ZC, $IC, $JC, $KC>.

$FDOC(template[,document]) |

Generate custom documentation Returns: Numeric |

This function makes a copy of a Microsoft Word (2007 and later) template (.dotx) file, substituting the placeholder text of Content Controls with the result of macro processor expressions, and saving the final result as a Microsoft Word document (.docx) file.

If the input template filename is specified with a relative or missing path, then the $FDOC function looks first in the ICAM_APPDATA directory and next in the ICAM_LIB directory. The template file can also reside in the post-processor internal file space (i.e., //ICAMFS).

The output document defaults to the same name and directory as the output listing file, with a file type of “.docx”.

The $FDOC function returns a value of 1 if the document was created and 0 (zero) otherwise.

Template Content Controls

The $FDOC function uses a Word template as the master file for the document creation process. Within the template, information to be extracted from the GENER process can be visually organized using the standard functionality of Word (e.g., headers, footers, text, tables…). Word provides various Content Controls (accessible from the Developer menu[1]) that can be used to embed the contents of ICAM macro expressions into the generated document. These content controls include:

Rich Text & Plain Text

Picture

Date Picker

Check Box (Word 2010 and later)

Combo Box & Drop-Down List

Group

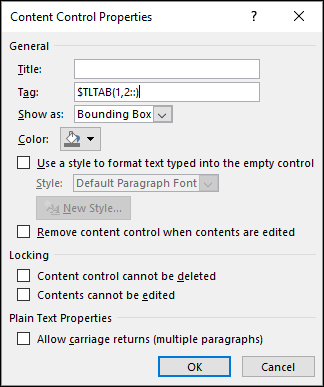

The link to the macro processor is done by typing an ICAM macro expression, variable name or constant into the “Tag” field of the content control[2]. The tag field macro code will only be compiled and executed when the template file is later processed in GENER calling the $FDOC function. The macro expression return value will replace the “placeholder” text originally shown for the content control in the template file. Tag macros have access to external and built-in functions, system variables, CNC variables (for Control Emulator CERUN), GLOBAL and OBJECT variables, as well as the LOCAL variables of the macro that called $FDOC.

Tag macros are normally prefixed with the string “$V_=” just before the macro is compiled. The $V_ system variable will hold the actual value to be substituted for the placeholder text in the content control when the tag macro is executed. If more complex macro logic is required, multi-line macros can be saved in a tag by using semicolons in place of line breaks (since these are not permitted in the Word Tag field). A multi-line macro must assign a value to the $V_ system variable before exiting.

$FDOC Tag macros are listed in the Macro Trace window. The $V_ variable can be watched in the debugger Variable window. The debugger Step-Into (F11) function can be used to step in tag macros. Breakpoints cannot be set on individual tag macros.

$FDOC unique range operators *, :: and ::: can be used with array variables and with sequences in Tag field macro expressions, to generate multiple rows of a table, one for each data element in the array or sequence. Range operators are only valid within Word tables and within areas grouped using the Group content control. All variables within a table or grouped area must have an identical range.

The * range operator selects all elements of the array or sequence. For example, $TLTAB(1,*) would produce one table row for each tool number in the tooling table.

The m::n range operator selects just those elements of the array or sequence starting at element m (default is 1 if omitted) and ending at element n (default is the array or sequence size if omitted). For example, $TLTAB(1,2::) would produce one table row for each tool number in the tooling table excluding the dummy tool. If the m or n components of a range expression contain characters other than digits, the range expression is separately compiled and executed to determine the range limits. These appear as $FDOC Range macros in the Macro Trace window.

The ::: ditto range operator is provided as a convenience and selects the same range as the first range operator defined in the table or grouped area. For example, $TLSUM(5,:::) would list the corresponding maximum tool feed rate information in the same table or grouped area as other information requested.

Range operator expressions are replaced by the system variable “$I_” just before the tag macro is compiled. The $I_ system variable will hold the actual range value for the current table row or grouped area when the tag macro is executed. The $I_ variable can be watched in the debugger Variable window.

Rich Text and Plain Text controls

The Text and Rich Text controls are nearly identical; the Text control provides an additional option to output multiple lines. The Tag macro expression result is converted at run-time to a text representation and then output in replacement of the original placeholder text.

If “Use a style” is selected in the content control Properties, the selected style is applied to the resulting text. If “Allow carriage returns” is selected and the Tag expression evaluates to a sequence, then each element of the sequence appears on a separate line in the generated document, otherwise a single space will separate each element of the sequence. If “Remove content control” is selected, then the generated document will appear the same but the content control will no longer be present (this simplifies the generated document).

Picture control

The Tag expression must evaluate to a STRING defining a filename containing an image in a format that is supported by Word (e.g., png, jpg, gif, tif, bmp). A filename with a missing path is taken from the same directory as is used by the $FMSPIC function. The specified image is resized (maintaining aspect ratio) to fit within the placeholder image area.

Date Picker control

The Tag expression must evaluate either to a STRING in ICAM date format (e.g., $DATE, $PPDATE…) or to a REAL value representing the number of seconds since an operating system specific “epoch” date (i.e., as returned by the $FSTAT function). The date is output in the generated document using the date picker Properties format string.

Check Box control

The Tag expression must evaluate either to a LOGICAL value where $TRUE specifies a checked state and $FALSE specifies an unchecked state, or to a REAL value where non-zero specifies a checked state and 0 (zero) specifies an unchecked state. The same font must be used for both the checked and unchecked character representations in the check box Properties.

Combo Box and Drop-Down List controls

The Tag expression must evaluate to a non-empty SEQUENCE, which will be used as the available choices that can be selected when later opening the generated Word document.

Group control

The $FDOC function will automatically repeat a single row of a table that includes macro variables with range operators. If two or more rows in the same table use range operators, then the $FDOC function will repeat the entire table for each instance of the range. If the repeated range must include more than just a single row or a single table, then the Group control can be used to identify the region of the template file to be repeated for each instance of the range.

Note that the Group control does not have a Tag field. The grouped region is repeated for each instance of the first range operator defined in the group. All other variables in the grouped region with range operators must specify the same range. The “:::” ditto operator can be used to ensure consistency.

$FERSEV(n1[,n2]) |

Get or set severity of error number Returns: Numeric |

This function returns the error severity (0 through 99) of error number n1. A severity of –1 (negative one) is returned if the error number is not known. The current severity can optionally be modified by specifying a second parameter n2 with the new severity value.

$FERSTA(n[,a]) |

Get or set enabled/disabled state of error number Returns: Logical |

This function returns the current state (enabled or disabled) of error number n. A status of $TRUE is returned if the error number is enabled for output. A status of $FALSE is returned if the error number is disabled (i.e., a diagnostic will not be output even if that specific error condition occurs). The current state can optionally be modified by specifying a second parameter a with a logical $TRUE or $FALSE value giving the required state. $FERSTA provides the same functionality as the PPFUN/15 command (see “Modifying Error Messages”).

$FERTXT(n) |

Text of error number Returns: String |

This function returns the error text of error number n. A blank string is returned if the error number is not known.

$FGETDEF(s) |

Get DEF file variable definition Returns: String or $NULL |

This function returns the value of the case insensitive DEF file variable named s. The variable name must be fully qualified with the names of all surrounding “begin” blocks in the DEF file (see the example below). The return value is a case sensitive string. $NULL is returned if the DEF file variable has not been defined or if some other error occurs while attempting to obtain the variable definition.

The following example gets the value of the “interface_kit” DEF file symbol:

%L01=$FGETDEF('campost.interface_kit')

$FGETENV(s) |

Get environment variable definition Returns: String or $NULL |

This function returns the value of a (potentially case sensitive) environment variable identified by the string s. $NULL is returned if the environment variable has not been defined or if some other error occurs while attempting to obtain the variable definition.

$FIK([[ q,] n]) |

Convert workpiece coordinates to machine coordinates Returns: Sequence |

This function returns the machine coordinate that would be output given the specified workpiece coordinate (see $FDK for the reverse functionality). The return value is a sequence of length 6, representing the machine axes positions as defined by the current $AXES system variable. The input is a sequence q of length 6 representing the workpiece XYZIJK tool position. Excess trailing zero sequence values are ignored. Missing trailing sequence values are replaced by the current workpiece position or tool axis vector component. The vector need not be normalized. $FIK ignores any effect due to pending rotary motions (via ROTABL/…,NEXT).

On 5 axis machines there can be 2 different machine configurations that satisfy the tool-to-part relationship specified by a CL coordinate. A second parameter to $FIK specifies the solution number n, as follows:

- 0:

Return solution #2 if it is the only solution inside travel limits, otherwise return solution #1. (default)

- 1:

Return the solution that has the shortest rotary component, or if rotary components are equal the shortest linear component, or if linear components are equal the first component computed. This is equivalent to the solution that would be chosen when LINTOL is active.

- 2:

Return the opposite solution of #1 if there is one, otherwise return the only solution.

Calling $FIK without a workpiece coordinate value returns the current actual or current alternate machine solution. Calling $FIK without any arguments, or with just the solution number set to zero, returns a sequence equivalent to <$XM, $YM…> for the current set of active axes.

$FINFO([[start,] end]) |

Return information concerning upcoming operation(s)

|

This function performs a look-ahead of the next operation and returns information about that operation via $INFO.* system variables. The $FINFO function returns a wide variety of information, such as operation starting and ending positions, feed and speed, compensations, flags indicating positioning and interpolation modes encountered, as well as custom data for user-defined purposes. “$FINFO Operation Look-ahead” describes the $FINFO function in detail.

$FKINCFG(axis,x,y,z,i,j,k ) |

Modify the position and orientation of a rotary axis or the tool axis Returns: Numeric |

This function internally sets the position and the orientation of a rotary axis or a tool axis. The axis identifier is either a whole number index or a keyword, as listed in the table below. The position and orientation of the axis is given by xyzijk data. This function returns a value of 1 (one) if successful; otherwise a value of 0 (zero) is returned.

Index

Keyword

Axis

0

TOOL

Tool axis

7

AAXIS,TABLE

Rotary A table

8

BAXIS,TABLE

Rotary B table

9

CAXIS,TABLE

Rotary C table

10

AAXIS

Rotary A head

11

BAXIS

Rotary B head

12

CAXIS

Rotary C head

14

RAM,1

Primary rotary on exchangeable head

15

RAM,2

Secondary rotary on exchangeable head

$FKINCFG(axis,OFF) |

Reset the position and orientation of a rotary axis or the tool axis Returns: Numeric |

This function resets the specified axis (see table above) to its original position and orientation as defined in the Questionnaire. This function returns a value of 1 (one) if successful; otherwise a value of 0 (zero) is returned.

$FLOOK(a1~[,a2]) |

Return information concerning a future event or processing state Returns: Numeric |

This function is used to invoke a generic look-ahead on an event a1. “$FLOOK Generic Look-ahead” describes the $FLOOK function in detail.

$FMACID( [string[,mask]] ) |

Find matching macro id’s Returns: Sequence |

The $FMACID and $FMACSTA functions are used to enable or disable individual macros. The $FMACID function obtains numeric identifiers of the macros to be enabled or disabled. The $FMACSTA function then interrogates or changes the state of the specified macros.

The $FMACID function searches through all macros for a match with the string, and returns a sequence containing pairs of “id,'description'” for each match. If the search string is blank or omitted, the current macro index and description is returned. Otherwise, the search string is compared against the first line of all user-defined macro SDL lines as well as the built-in names for startup, shutdown and event macros (including those of the Model and CAM interface kit).

The search string can contain special characters in the form of a regular expression (RE). For example, the search string '.' will match all macros. See the $FEDIT function for description of RE’s.

The candidate macros to search can be restricted using combinations of the mask value, as follows. If mask is omitted, all macros are searched. Note that composite post-processors cannot match or modify macro states in another component, nor in the composite master (and vice versa).

Mask

Macros to search

1

post-processor macros

10

Model macros

100

CAM interface before and after macros

If no macro matches the search string, then an empty sequence is returned. Otherwise, the sequence will contain two elements for each matching macro. The first element of the pair is the macro index number. The second element of the pair is the macro description. This return sequence can be used with the $FMACSTA() function to enable or disable the matched macros.

$FMACSTA(seq[,state]) |

Set or query enabled/disabled state of multiple macros Returns: Sequence |

$FMACSTA(id[,state]) |

Set or query enabled/disabled state of a single macro Returns: Sequence |

The $FMACID and $FMACSTA functions are used to enable or disable individual macros. The $FMACID function obtains numeric identifiers of the macros to be enabled or disabled. The $FMACSTA function then interrogates or changes the state of the specified macros.

The $FMACSTA function returns the current enabled ($TRUE) or disabled ($FALSE) state of macros identified using the $FMACID function. If a logical state is specified, the macro states are changed accordingly (the returned value is the enabled/disable state before applying the change). Macros can be specified either by a sequence seq containing macro id’s (non-numeric entities in seq are ignored) or by a simple numeric id. The returned sequence contains pairs of “id,state” for each macro, where id identifies the macro and state is a logical variable set $TRUE if the macro was enabled.

For example, the following disables all COOLNT user-defined macros in the post-processor:

%L01=$FMACSTA($FMACID('^COOLNT'),$FALSE)Either of the following re-enables all COOLNT user-defined macros:

%L01=$FMACSTA(%L01,$TRUE) %L01=$FMACSTA($FMACID('^COOLNT'),$TRUE)The following inverts the enabled/disabled state of all COOLNT user-defined macros:

%L01=$FMACSTA($FMACID('^COOLNT')) DO/I=1,$FLEN(%L01),2 %L02=$FMACSTA(%L01(I),.NOT.%L01(I+1)) ENDOF/DO

$FMRU… |

The $FMRU family of functions are designed to simplify the saving and restoring of MRU “most recently used” information, such as user responses to interactive dialogs.

MRU data is stored on disk in XML format. When called from a post-processor macro, the MRU file will by default have the same name as the post-processor and be stored in the same directory as the post-processor database. When called from a model macro, the default name and directory are those of the model name and database respectively.

The MRU file is organized at the highest level using named keys. Key names are strings that uniquely identify the information stored with the key. For example, if MRU data should be remembered between runs of the same input file, then the key name should be based on the input file name (this is the default). If MRU data is to be remembered for individual users, then the string returned from $FGETENV('USERNAME') would make a good key. If information is to be remembered regardless of input file or user, then a key name such as '*' could be used (i.e., something that won’t conflict with a valid file or user name).

Each key in the MRU file can have zero or more parameters. Each parameter has a name that identifies the parameter and a value. Parameter names are strings that can be anything other than blank. Parameter values can be any macro data type, including sequences. Named parameters eliminate the requirement to know the order in which they are saved in the MRU file.

The following functions are available:

- Opening:

- Closing:

- Keys:

- Parameters:

$FMRU_GETPARAM, $FMRU_GETPARAMS, $FMRU_SETPARAM, $FMRU_DELPARAM, $FMRU_DELPARAMS

The following is an example of how to remember a user’s response to a dialog box entry. For demonstration purposes, the dialog is named “Startup” and the dialog box entry to remember is a logical variable named “DLG_X”. Defaults are used for both the MRU file and the key name. The parameter name is “X”.

DECLAR/LOCAL,REAL,H H=$FMRU_OPEN() DLG_X=$FMRU_GETPARAM(H,0,'X',$TRUE) IF/$FDIALOG('Startup').EQ.'OK' %L01=$FMRU_SETPARAM(H,0,'X',DLG_X) ENDOF/IF %L01=$FMRU_CLOSE(H)

$FMRU_CLOSE( handle ) |

Close an MRU file Returns: Numeric |

This function writes out all changes and then closes the MRU file identified by the numeric handle (returned from $FMRU_OPEN). The function returns a numeric status value of 1 if successful. A return value of 0 indicates an error where $ERRNO contains the actual error code. $NULL will be returned if handle does not point to an open MRU file.

$FMRU_DELKEY( handle[,key ]) |

Delete a key in an MRU file Returns: Numeric |

This function deletes the specified key (string or numeric) from the MRU file identified by the numeric handle (returned from $FMRU_OPEN). If key is omitted, blank or zero, then the key name to delete is derived from the input file. The function returns a count of the number of keys deleted (i.e., either 0 or 1). $NULL will be returned if handle does not point to an open MRU file.

$FMRU_DELKEYS(handle[,sequence]) |

Delete multiple keys in an MRU file Returns: Numeric |

This function deletes the key names and/or key id’s specified in sequence from the MRU file identified by the numeric handle (returned from $FMRU_OPEN). If sequence is omitted, all keys are deleted. The function returns a count of the number of keys deleted. $NULL will be returned if handle does not point to an open MRU file.

$FMRU_DELPARAM( handle, key, param) |

Delete a key/parameter value in an MRU file Returns: Numeric |

This function deletes the parameter named param associated with the key in the MRU file identified by the numeric handle (returned from $FMRU_OPEN). If key is blank or zero, then the key name is derived from the input file. The function returns a count of the number of parameters deleted (i.e., either 0 or 1). $NULL will be returned if handle does not point to an open MRU file.

$FMRU_DELPARAMS( handle, key [,sequence ]) |

Delete multiple key/parameters values in an MRU file Returns: Numeric |

This function deletes the parameters specified in sequence associated with the key in the MRU file identified by the numeric handle (returned from $FMRU_OPEN). If key is blank or zero, then the key name is derived from the input file. If sequence is omitted, all parameters of the key are deleted. The function returns a count of the number of parameters deleted. $NULL will be returned if handle does not point to an open MRU file.

$FMRU_GETKEY(handle[,key ]) |

Get specified or default key in an MRU file Returns: Numeric |

This function looks in the MRU file identified by the numeric handle (returned from $FMRU_OPEN) for a key matching the name specified. If the key name is omitted or blank, then the key name to find is derived from the input file using $FBASNAM($CLNAME,'.'). The function returns a numeric key identifier that can be used in all other $FMRU functions wherever a key name is required. A return value of 0 indicates that the key name does not exist. Note that when writing MRU information, a key id value of 0 will save the MRU information under the default key name derived from the input file. $NULL will be returned if handle does not point to an open MRU file.

$FMRU_GETKEYS(handle [,order ]) |

Get all keys in an MRU file Returns: Sequence |

This function returns all of the keys in the MRU file identified by the numeric handle (returned from $FMRU_OPEN), either in order of when they were last updated (order=0, the default) or in ASCII collating order (order =–1 descending, order =+1 ascending). The function returns a sequence of key name strings. An empty sequence will be returned if the MRU file is empty. $NULL will be returned if handle does not point to an open MRU file.

$FMRU_GETPARAM( handle, key, param [,default-value]) |

Set a key/parameter value in an MRU file Returns: Any |

This function returns the value associated with the key-name/parameter-name combination in the MRU file identified by the numeric handle (returned from $FMRU_OPEN). If key is blank or zero, then the key name to find is derived from the input file. The parameter name param must not be blank. The function returns whatever value was originally stored in the MRU file using the $FMRU_SETPARAM function. If the specified key or parameter name does not exist, then the function will return the default value if specified, or will return $NULL if a default is not specified. $NULL will also be returned if handle does not point to an open MRU file.

$FMRU_GETPARAMS(handle[,key]) |

Get all parameters for the key in an MRU file Returns: Sequence |

This function returns all of the parameter names associated with the specified key in the MRU file identified by the numeric handle (returned from $FMRU_OPEN). If key is omitted, blank or zero, then the key name to find is derived from the input file. The function returns a sequence of parameter name strings. An empty sequence will be returned if the key does not exist in the MRU file or if the key has no parameter values. $NULL will be returned if handle does not point to an open MRU file.

$FMRU_OPEN([filename] ) |

Open an MRU file Returns: Numeric |

This function opens an MRU file. If filename is omitted or blank, then the default filename is the post-processor or model name (depending upon which object the macro processor is running from). If the path portion of the filename is missing, then the default path is the directory containing the post-processor or model database. An empty MRU file is created if one does not already exist.

The function returns a numeric handle value that must be used in all other $FMRU functions to identify the MRU file being used. A return value of 0 indicates an error where $ERRNO contains the actual error code.

$FMRU_SETPARAM(handle, key, param, new-value) |

Set a key/parameter value in an MRU file Returns: Any |

This function writes the new value to the key-name/parameter-name combination in the MRU file identified by the numeric handle (returned from $FMRU_OPEN). If key is blank or zero, then the key name to write is derived from the input file. The parameter name param must not be blank. The function returns whatever old value was previously stored in the MRU file for the key-name / parameter-name combination being set. $NULL is returned if this is the first time writing this parameter data. $NULL will also be returned if handle does not point to an open MRU file.

$FOPPATH(...) |

Access to the generated list of positioning motions Returns: Sequence. |

This macro function forms an extended version of $FAPPOS() macro function. The major difference is that $FAPPOS() was applicable only to SmartPATH generated positioning sequence. $FOPPATH() applies also to other optimization motion sequences. In particular, this function provides access to Rotary-Turn-Around (RTA) positioning sequence, to LINTOL Path Planning positioning sequence (LPP), to LPP sequence generated by LIMIT/POLAR,...,SCAN,ON singular optimization and to variants of the motion lists re-generated by SmartPATH.

The first form of the function call returns general description of the motion list, if any is present.

PATHDESC=$FOPPATH() will return the following information:

- PATHDESC(1) returns type of the 0: no list is present 1: SmartPATH positioning motion list is present (AP) 2: Lintol Path Planning posiitoning motion list is present (LPP) 3: Rotary Turn Around motion list is present (RTA) - PATHDESC(2) Total number of motions on the list - PATHDESC(3) CL record number of the first motion on the list - PATHDESC(4) CL record number of the last motion on the list - PATHDESC(5) *id* of the first motion on the list moving rotary axis - PATHDESC(6) *id* of the last motion on the list moving rotary axisMOTDESC=$FOPPATH((id|AUTO)[,type]) returns motion description.

This function is used to examine the motions present on a RTA, LPP or AP positioning sequence. The id parameter specifies the motion number for which information is desired. The total number of motions generated in the positioning sequence can be obtained using the PATHDESC(2) after $FOPPATH() is called.

AUTO or $OPPATHI macro variable can be used to retrieve data of the next move to be processed.

Specifying an id outside of the range 1:PATHDESC(2) will result in a $NULL sequence being returned.

PATHDESC(2:3) indicates the range of CL motions that are being matched and replaced by generated motion sequence. All RTA motions are matching one particular CL motion. Path Planning (LPP) motions are having, typically, one-to-one correspondence between CL GOTOs and list motions. Exceptions are cases when the user is asking for RTA-like sequence to be generated, to increase safety of LPP positioning in case when SmartPATH is not available. In case of SmartPATH generated motions all combinations are possible. In other words, many CL motions can be replaced by one SmartPATH generated move and one CL motion may be replaced by many SmartPATH generated motion. When processing, the general rules are that the first CL motion in the sequence is matched and replaced by first SmartPATH motion in the sequence. The last CL motion in the sequence is matched and replaced by all remaining, SmartPATH generated moves. Any remaining CL motion between first and last are omitted (skipped) by the process. No actions should be forced, generated for these motions! The “skip” action is indicated by MOTDESC(4)==1.

The type of motion data Indicates the frame in which returned coordinates are expressed:

- 1:

CL part frame, equivalent to the $P2 motion macro variable

- 2:

Machine frame, equivalent to $XM, $YM… macro variables

- 3:

Workpiece frame, equivalent to the $P3 motion macro variable (default)

Invoking MOTDESC=$FOPPATH($OPPATHI) will return the following information:

- MOTDESC(1): It returns the sequence number of the motion on the list. If $OPPATHI was utilized to call the function its value will be repeated here - MOTDESC(2): ID of the motion. Similar to current $RTAID, $SCANID, $APID whichever is applicable - MOTDESC(3): Returns matching CL record number. Typically, all RTA motions are matching the same CL record number, the same GOTO motion, LPP motions are often matching CL motions uniquely, and for SmartPATH the match is arbitrary. Many SP motions can match single CL motion. - MOTDESC(4): 1: skip the motion, 0: do not skip, execute the motion. Once the motion is matched against the CL motion a scheduled action can be 0: execute the generated motion instead of CL motion. This is always the case for RTA and LPP list. For SmartPATH list the action can 1: skip the motion or 0:execute. When the action is 1:skip then nothing is output for this list motion. - MOTDESC(5): Algorithm type that generated the motion. For example, an RTA motion list can be constructed of SmartPATH motions. This information is provided mostly for debugging, in case of an unexpected result. - MOTDESC(6:11): Coordinates of the motion specified as per *type* argument. Checking coordinates of upcoming or just executed motion the pos-processor developer can decide if specific motion “decoration” should be output, if the specific NC codes need to be OUTPUT.

$FPAUSE([string]) |

Pause processing with optional message Returns: Logical |

This function will pause GENER processing and display a message-box with the specified or default string. The user will be given a choice to either pause or continue processing. When paused, the full GENER interface is made active. Once GENER processing resumes, this function will return a logical value of $TRUE if the user chose to pause processing, or $FALSE otherwise.

The message-box is not displayed when running in background mode. Instead, the $FPAUSE function immediately returns a value of $FALSE and processing continues uninterrupted.

$FREGFMT(a) |

Return $FSWRIT compatible output format for register Returns: String |

This function takes as input either a register index number, or a text string matching one or more characters of a register’s descriptor. It returns a format string that can be used with the $FSWRIT() function to output a register value. This function was designed to be used in the register macro to modify register values.

$FREGPOS(string) |

Return a register index given a register descriptor Returns: Numeric |

This function takes as input a text string matching one or more characters of a register’s descriptor. It returns the register index number or –1 if a match cannot be found. This function was designed to be used in the register macro.

$FSORT(infile, outfile [,delimiters] ~[,field,type,order]) |

Sort records in a file Returns: Numeric |

$FSORT(sequence [,fields ~[,field,order]]) |

Sort elements of a sequence Returns: Sequence |

This function can be used to sort the contents of a file or the contents of a sequence variable.

When sorting a file, the contents of the input file are first read into memory, sorted, then written to the output file. The same file name can be specified for both input and output files. Sorting occurs on specific fields (or columns) of data in the file. By default, a run of spaces defines the boundary from one field to the next. Specify an optional delimiters string to define a different character or set of characters to be used as field separators (e.g., specify $FCHAR(9) to use a tab character as a delimiter). The default increasing ASCII text order of sorting can be changed by specifying a “field,type,order” sort key parameter, where: field identifies a field number; type is a string 'N' or 'S' defining a numeric or string field type; and order is one of the keywords INCR or DECR. Additional sort keys can be specified to further sort records with matching sort key fields. If all sort keys are the same, then the original record order is maintained (i.e., a “stable” sort). The $FSORT function will return the number of records in the output file, or –1 if the sort failed. The $ERRNO system variable will be set to a non-zero value if the sort failed.

When sorting a sequence, the input sequence is specified as the first parameter of the $FSORT function and the sorted result is returned as a sequence. If all elements of the sequence are the same type (e.g., all numbers or all strings), then $FSORT can be called with just the input sequence to sort the elements in increasing order. If the sequence represents a table (e.g., alternating pairs of number and string elements), then the fields parameter must be specified to tell the sort function the number of fields (or columns) that make up each record (or row) to be sorted in the sequence. The default increasing order of sorting can be changed by specifying a “field,order” sort key parameter, where field identifies a field number and order is one of the keywords INCR or DECR. Additional sort keys can be specified to sort records with identical sort key fields. If all sort keys are the same, then the original record order is maintained. If the sort fails, a null sequence (i.e., $NULL) will be returned and the $ERRNO system variable will be set to a non-zero value.

$FTLTAB( [[ start,] end ] ) |

Scan CL file for tool changes Returns: Sequence |

This function scans forward in the CL file looking for tool change operations (e.g., LOAD, UNLOAD, LOADTL and TURRET) and returns a sequence of $TLTAB indices identifying the tools loaded, in the order that they were loaded. An empty sequence is returned if no tool change operations were encountered during the scan.

The start and end CL record numbers are optional.

If omitted or zero (0), the end CL record defaults to the end of the CL file. Note that when called while a subprogram is active, the end of file is actually the end of the subprogram. Also note that with Composite post-processors, the end of the scan will occur when an APPLY command is encountered that switches processing to a different component post-processor.

If omitted or zero, the start CL record defaults to the current CL input position (i.e., the next CL record to be read). Calling $FTLTAB without any arguments causes a scan from the current CL input position to the end of the CL file or subprogram.

The $TLTAB tooling array is updated for any tool encountered during a $FTLTAB scan, so that tooling information can be obtained using the returned $TLTAB index values.

The following example lists the tool number and tool name of every tool loaded up to the next BREAK command (if any):

SEQ=$FTLTAB($FGET(BREAK)) DO/I=1,$FLEN(SEQ) J=SEQ(I) PPRINT/'!(*) - !(*)',$TLTAB(1,J),$TLTAB(20,J) ENDOF/DOMacro processing is enabled during the $FTLTAB scan. If necessary, the $TLOOK and/or $LOOKAH system variables can be used in macros to determine if a look-ahead is active. The $FTLTAB function does not affect the current CL file location.

$FUNWIND( axis [,modifier] [,…] ) |

Reset rotary axis to modulo-360 value Returns: Numeric |

This function internally resets one or more rotary axes to their modulo-360 value. No motion is generated. Specify the axis using either a whole number index or a keyword, as listed in the table below:

Index

Keyword

Axis

0

TOOL

Tool axis

7

AAXIS,TABLE

Rotary A table

8

BAXIS,TABLE

Rotary B table

9

CAXIS,TABLE

Rotary C table

10

AAXIS

Rotary A head

11

BAXIS

Rotary B head

12

CAXIS

Rotary C head

14

RAM,1

Primary rotary on exchangeable head

15

RAM,2

Secondary rotary on exchangeable head

An optional modifier keyword can be specified to control the 360-degree range of the final rotary axis position, as follows:

- NORMAL:

Range [–179.9999,180] (the default)

- PLUS:

Range [0,359.9999] forces a positive result

- MINUS:

Range [–359.9999,359.9999] respects the current axis sign

Multiple rotary axes can be reset by repeating the “axis [,modifier]” specification for each additional axis to be reset.

This function returns a value of 1 (one) if successful; otherwise a value of 0 (zero) is returned.